Custom cables

With over 30 standard insulation and jacket materials and a wide range of approvals and manufacturing capabilities, we work closely with our customers to find smart solutions that match their application and budget.

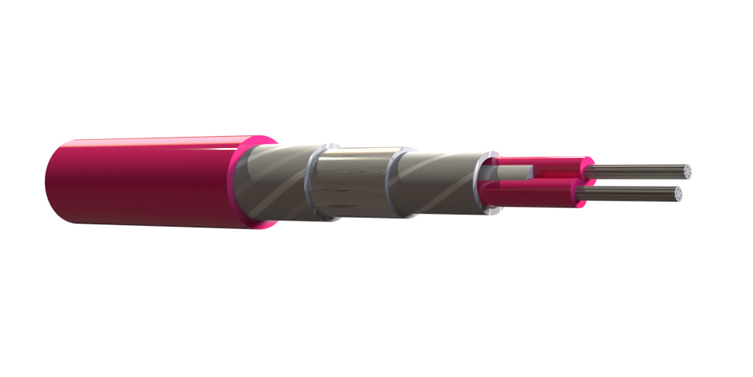

Insulation and sheath are the plastic components of a cable that protect the conductor. The insulation isolates the flow of electricity, and the sheath wraps around the outside of the cable to protect the conductors inside and enable electricity transmission.

The choice of material used for insulation and sheath can have a significant impact on the overall performance of a cable, and there are a number of key factors to consider when choosing the right material for your application:

There are a number of different groups of materials. Each has its own distinct properties, benefits and uses. Chemically pure materials are often ideal for use as insulation, when superior electrical performance is required. Materials such as PTFE and HFI 90 provide high insulation resistance and low dielectric loss. For sheathing, the outer environment and the demands for resistance to fire are the key factors.

Fluoropolymers are halogenated high temperature materials that are intrinsically highly flame retardant. They do not generate much smoke and have exceptional electrical properties. Fluoropolymers are also excellent when it comes to mechanical strength and elasticity, resistance to oil, fuel and chemicals.

Polyolefins can withstand temperatures up to 100ºC. It can be cross-linked to improve chemical resistance, mechanical and thermal properties. Polyolefins has excellent electrical properties, good chemical and radiation tolerance and is also abrasion resistant. It has excellent mechanical properties and is suitable for use in water.

HFFR (halogen free flame retardants) Polyolefins are lower temperature halogen free materials that are made fire resistant with halogen free flame retardants. In most cases they are thick wall materials used for jacketing. Some HFFR - Copolymers can be used up to 130 degrees Celsius.

Polyesters such as TPS 100 are generally higher temperature materials than polyolefins and can be used thinner due to their tougher nature. It can be flame retarded with Halogens or with Halogen free flame retardants. Polyesters are characterized by their excellent mechanical properties with great toughness. They are also fuel and oil resistant and can withstand some exposure to water, acids and bases.

Polyurethane is a good choice for sheathing as it has excellent mechanical properties; it is very tough and has abrasion resistance. It can be flame retarded with halogen free flame retardants but is not suited for use as insulation (it has poor electrical properties). Polyurethanes has excellent water and oil resistance and is resistant to fuel, acid and base. The material is also resistant to radiation and ozone and has excellent flex-life.

PEEK is a very tough material for specialist high performance cables. The material is similar in many ways to fluoropolymers, but without the halogen content. It is very difficult to process. Special characteristics are excellent mechanical properties and chemical resistance. It is also resitant to fire, generates low smoke and toxes. PEEK has also excellent radiation and abrasion resistance.

Polyolefin or silicone based rubbers such as HFR 150, MPR 100 and MPR 105 tend to be highly flexible and have good temperature ranges. Their insulation resistance is also fairly good making them usable as both jacket and insulation. As they are so soft and flexible they need to have high wall thicknesses. Rubber-like materials have varying chemical and water resistance.

At Habia, we specialise in designing and manufacturing custom cables and harnesses for demanding applications. With access to over 30 different insulation and sheath plastics, our experienced designers and engineers can provide the ideal solution for any application.